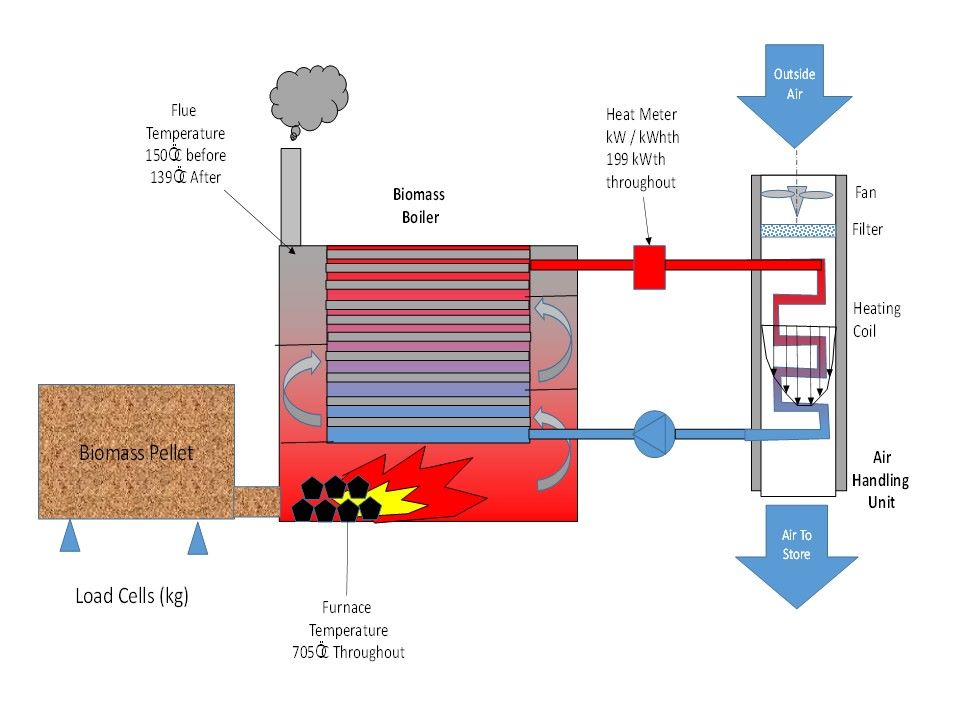

Biomass Boilers

Biomass Boilers provide a source of renewable heat and can be registered for RHI’s with the UK government. However firstly to be eligible the fuel must be appropriate – this can be determined by checking the “Biomass Suppliers list” operated by OFGEM. Secondly the Boiler must be registered on OFGEM’s “product eligibility list”. Finally it is necessary to demonstrate that the heat is being used “usefully” and not being wasted purely to receive payment for RHI’s. By complying with the “product eligibility list” the manufacturer must demonstrate that the boiler meets UK emissions criteria, although for planning it will also be necessary to demonstrate that the boiler will not have an adverse impact on the local environment through dispersion modelling.

The cost of Biomass Fuel is c 3.5p/kWh with the RHI’s worth c 2.4p/kWh(th) for boilers between 200kW and 1MW as at February 2018. Typical thermal efficiency is 70% at 50% load increasing to 80% at full load.

.

When designing a Biomass boiler, one must consider that it is a solid fuel boiler and as such will be less reliable that as gas fired boiler as there are more variables. Consistency of fuel is a key factor and standards exist (EN 14961-2 and ISO 17225-2). EN-Plus pellets originated in Germany but are now commonly available in Europe. The second factor to consider is the delivery mechanism of pellets to the fuel hopper and ensuring that the pellets are not damaged in the hopper or whilst being transported to the furnace. If the fuel becomes damaged, wood dust can give rise to hot spots in the furnace and can damage both ironwork and the furnace lining.

In terms of design, as Biomass Boilers have large water jackets and considerable thermal mass, it has been found that a biomass boiler 20% smaller that an equivalent gas boiler will carry the same duty.

Care must be taken when handling and disposing of the ash as it is both high in silica dust and lime (calcium oxide).